By: HellKnightHicks

Sept. 19, 2013

Please read the disclaimer page

Please visit our FORUM. All discussion, questions and comments about this article are welcome.

The modifications we will discuss here will work on just about any Saginaw style power steering pumps out there. If it’s got the flow piston, these modifications will work.

If you choose to perform any of these modifications, they are all done at your own risk.

Disassembly and Parts

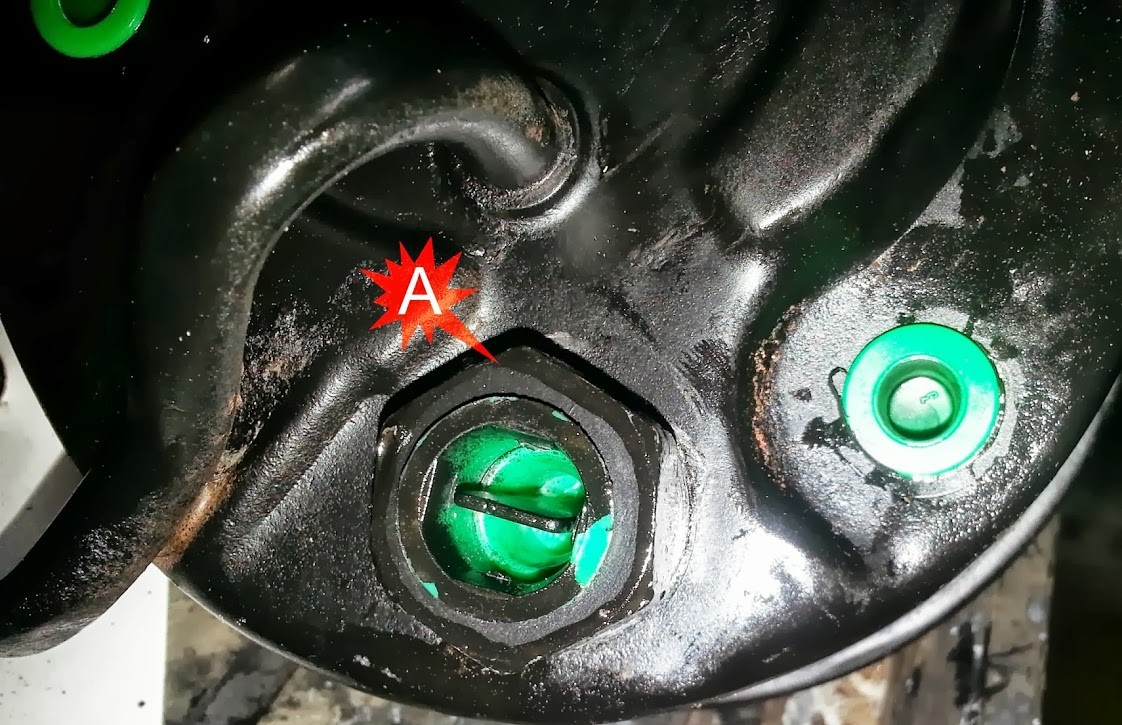

First you need to pull the servo/valve assembly out of the power steering pump. This can be done with a 1” socket and an impact hammer.

Item A in the following photo is the portion of the pump that can be unscrewed.

After removal of the fitting you will see the flow piston. If it did not come out you can take it out with a magnet. There is a spring behind it, you will need to take that out also.

When removing it from the truck you should expect some, if not all, of the fluid to slowly drain from the pump.

When it all comes out it looks like this

A = Main fitting (The part the hose screws into)

B = Piston Spring

C = Flow Piston (Contains the High pressure Bypass)

Now onto the actual modifications

Idle/Low RPM Flow Modification

The fitting orifice controls the volume/speed that the pump can use to restore operating pressure (flow piston controlled). The larger the hole the more fluid the pump is able to use to respond the power steering pumps use of pressure.

Example: You turn steering wheel left. The gear box uses pressure built up in the system and the pump must restore pressure to the line. You will see it be very easy/quick at first few degrees of wheel rotation which slows shortly after as the pump is not able to keep the line pressure up.

Keep in mind that the pump can only pump so much at any given RPM, the assistance will always vary regardless of orifice size. But we can maximize the pumps ability to compensate in a timely manner.

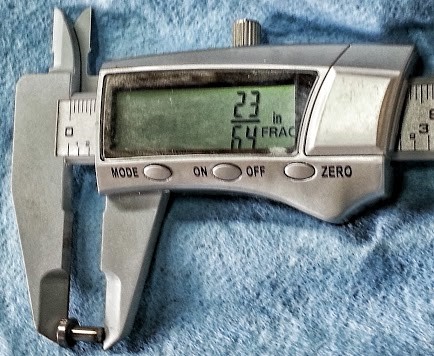

You can use drill bits to determine the size of the opening inside of the main fitting. If you would like to make minor adjustments to gradually increase the size of the orifice.

If your fitting hole is smaller than 5/32 enlarge the hole to 5/32.

I have had the best results when drilling the fitting to 5/32. This seems to be a good spot for responsiveness without over-doing it. I may go larger at a later date but right now I’m content with 5/32 opening.

The 3500 hydro-boost power steering pumps have a 5/32.

The 1500 Pumps I have worked on have 1/8 had a much smaller orifice.

I have not been able to find information about orifices larger than 5/32. Please let us know of your experiences with larger orifices.

Increase Pressure Hold duration at Higher RPM’s

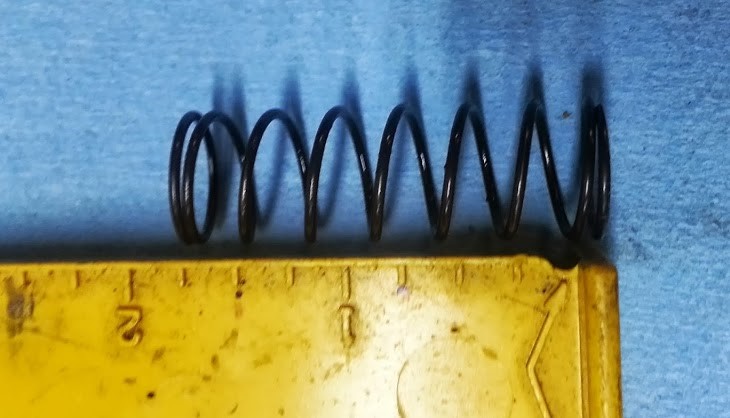

This spring keeps the flow piston pushed against the flow orifice.

Take the piston spring shown above. (This is the spring that sits outside the flow piston NOT the one from inside the flow piston)

Using a ruler or tape measure stretch this spring out to 2 ¼ inches. This will help the pump hold the pressure as the RPMs increase. The flow piston will still close but will reduce the speed at which it does so.

I have tested with a spring that was 2 ½ incheslong and it seemed to cause the flow piston to stick in the closed position. This was in combination with the end cap being screwed down with no spacers. Push the gas just a little and it pops lose…

Increase Pump Pressure

The flow piston controls the amount of pressure the system has. Pressure modifications will be done here.

Above are flow pistons from stock setups.

From left to right

Piston #1 and #2 are approximately 1100~1200 PSI

Piston #3 is a 1050~1100 PSI

Piston #4 is a 900~1000 PSI

-Precautions/Warnings

You can damage you Gear Box seals or blow hoses by increasing the pressure to much. Do understand if you have a car with 200,000 miles or many years on it that your hoses may be weak. If you have a leak before making changes here it WILL be worse. You may want to put new pressure lines on your setup before preforming the following modifications.

Increasing the pressure, without a doubt, will increase parasitic loss from the power steering pump. More pressure means more push but it also means it takes more power to run it.

-Disassembly

Place the flow piston in a vice, clamping the front and back outer rings, I put a nitrite glove around mine to help prevent scuffing. Heating it up with a propane torch can help loosen the loc-tight if you have any in it. Out of the ones I’ve taken apart, they were a little bit difficult but required no heating. Even though the piston is tough, I didn’t scratch any of them either.

Using a 7/16 wrench unscrew the end cap.

There’s a BB behind the end cap. Don’t lose it.

Then there’s the limiting stud and spring.

Now that we’ve opened up the flow piston, let’s go over the parts inside.

From left to right

End Cap – Has screen in the top of it to catch particles too large to pass through.

Shim/s - Just under it would be Shims if I had any. Notice the empty space between it and part number 1 and 2

Check Ball/BB – Used to seal the Orifice.

Limiting Stud – Used to keep the check system from completely compressing.

Spring – Controls actuation rate.

Piston Housing – let’s just say it holds all the bits together.

- How it works

Check ball or BB moves out of the way and allows pressure bleed off to occur. The stronger the spring the higher the pressure.

-Modifications

Remove the washers/loc-tite, crank your end cap down until flat, this will increase your pumps holding pressure to 1350~1400, which is factory maximum. Production pumps don’t come with any higher pressure flow pistons than that.

-For more pressure than stock setups

You can place washers in the bottom inside of the Piston Housing.

3mm washer – Will increase the pressure slightly (Requires limiting stud modification)

#4 Machine Washer – Pressures to around 1400 PSI plus. (Requires limiting stud modification)

2X #4 Machine Washer – pressures undocumented. A number of off-roaders user this (Requires limiting stud modification)

This is the highest pressure mod that I have read about.

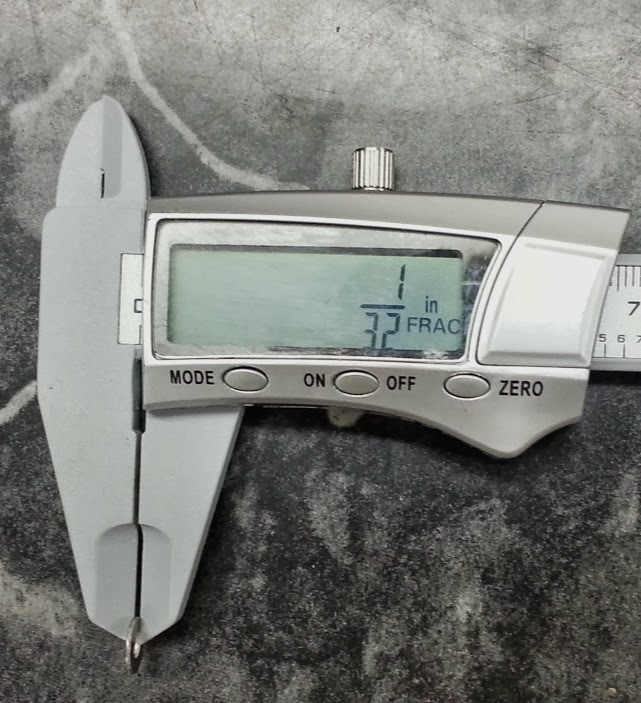

(Limiting stud modification)

You will need to grind ~1/8” off of the bottom of the limiting stud after adding a washer/s in order for it to continue to function properly. If not modified you run the risk of the bypass jamming shut. That would cause a drastic spike in pressure.

The 2 x #4 machine washers are used by a number of off roaders to enable them to ram around those large tires on rock and to help boost the RAM assists.

The washers go in the bottom of the flow piston

-Summary of pressures

| Spacing | PSI | Notes |

| Tall housing w/shim | 900~1000 PSI | stock |

| 2 shims | 1050~1100 PSI | stock |

| 1 shim or Loc-tite | 1100~1200 PSI | stock |

| Flushed end cap | 1350~1400 PSI | stock |

| + 1 #4 machine washer | ~1400+ | Requires limiting stud modification |

| + 2 #4 machine washers | undocumented | Requires limiting stud modification |

-Ending comments.

If you have any personal experience or modifications you have done to your pumps please share.

Thanks for reading.