By: HellKnightHicks

Thanks to: Joecar, TAZ

Mar. 27, 2013

Please read the disclaimer page

Please visit our FORUM. All discussion, questions and comments about this article are welcome.

Alright so you have a 4L60e and you want make it live as long as possible behind your heavy foot and that maybe beefy engine. Here’s what I did with some help from some professional tuners.

All tables and graphics referenced in this guide are from EFILive, and all changes were made using EFILive.

This guide covers establishing a solid base tranny tune that will encourage the longevity of the transmission.

These instructions were originally made for a built 4L60e transmission with an aggressive shift kit and upgraded hard parts (not to say the changes won’t work well on a stock tranny because they should).

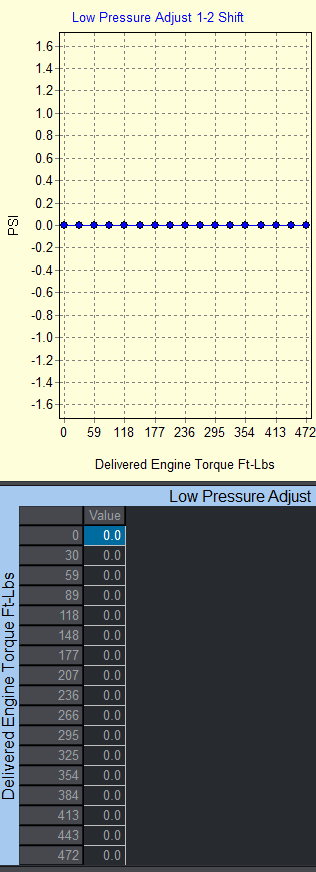

First things first. If you have a shift kit or just want more consistent shifts we are going to disable the “Low Pressure Adjust”. This will prevent the computer from removing the effects of your shift kit and/or increases you’ve asked for in the line pressure. Basically the computer will always have to command at least what’s provided in the pressure tables.

D1101 Low pressure Adjust 1-2 change to 0's

D1102 Low pressure Adjust 2-3 changeto 0's

D1102 Low Pressure Adjust 3-4 change to 0’s (D1102 Should Already be 0’s)

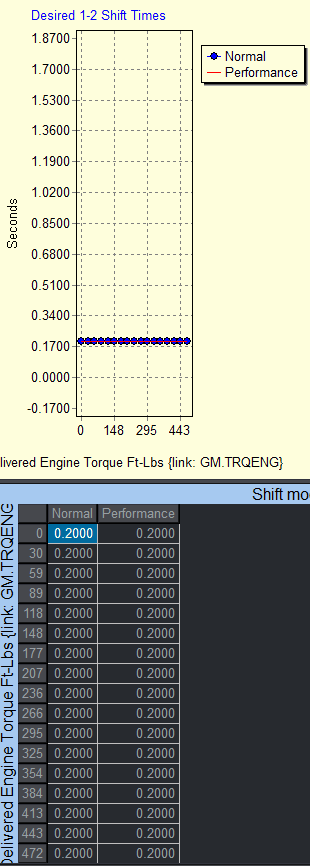

Long shifts provide that nice cushy feel but it's really hard on the clutches. We don’t want the computer trying to lengthen the shift times which is contrary to what the shift kit is trying to do. It would be better to use TQ Management to soften your shifts if that is your preference.

D1108 – Set entirely to 0.2

D1109 – Set entirely to 0.2

D1110 – Set entirely to 0.2

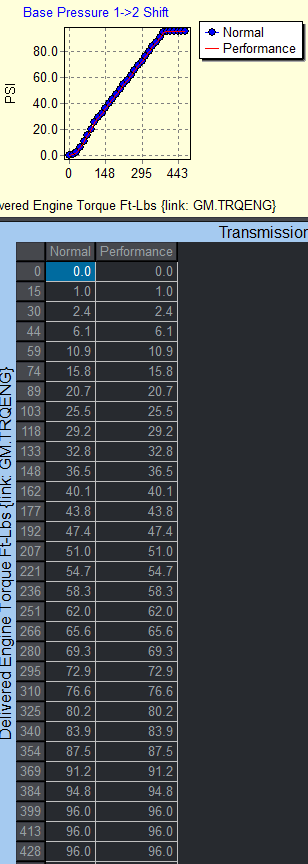

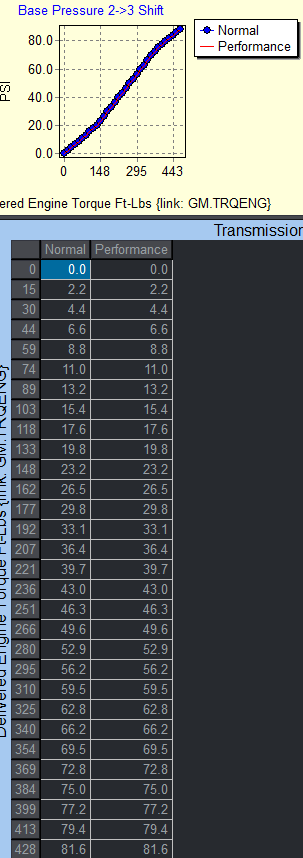

For performance purposes you should have at least 60~80 PSI by 395HP in your pressure tables. According to research by “joecar” These indirectly effect the control line pressure during a shift.

Adjust these pressures for the following tables:

D0701

D0702

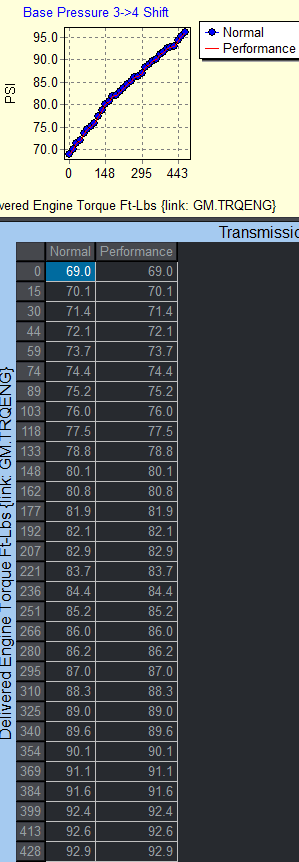

D0703 (see below)

If you would like to test your setup you can install a 300PSI gauge in the tap on the tranny. At WOT it should be somewhere around 180~220PSI depending on the build of the tranny.

if it's below that then you have to address this (VE/MAF tables and physically inside trans).

D0703 notes

You can flat line this to 96PSI to get a good firm shift out of your 3>4 gear changed.

Apparently in competition use and A4 T42 Controllers these tables are set to 90PSI.

In the displayed example I went for a slight trend. I may change that latter to 96PSI all the way across the board.

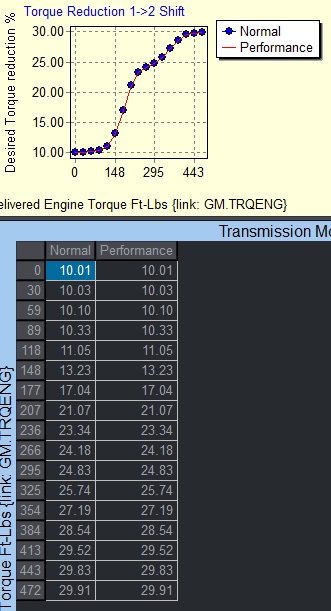

Torque (TQ) Management and Reduction

As far as TQ Management or TQ Reduction that’s a personal preference thing. It can be reduced a ton from the factory tables depending on your preferences, and goals. Many people simply alter these tables by a specific percentance to decrease (or increase) torque management and reduction:

D0801

D0802

D0803 – I Zeroed this one

I'm still working on my TQ reduction tables to get the desired shifts. What you like may not be what someone else likes, and preferences for such will vary from person to person. Realize that removing torque management may or may not result in a reduction in transmission longevity, and therefore needs to be done with that understanding.