By: HellKnightHicks

Mar. 23, 2013

Please read the disclaimer page

Please visit our FORUM. All discussion, questions and comments about this article are welcome.

First off I’d like to say that these are some of the first things that I've learned while tuning. I'm not responsible for any damages you cause to your setup by modifying these settings (please read the disclaimer). I'll do my best to guide you with the information that I have available to me and from my own experiences.

These are all things that most tuners change when doing a wake up tune. These adjustments can really make your engine respond quicker and have less hesitation. Brake Torque Management (BTM) removal will also help keep your truck from gearing down on those tough grades. I couldn’t believe the difference that these changes made to my heavily modified 383.

The base tune used in these examples is a Vortec 411 base file found in the 12200411 swap article. We are using EFILive to perform all our tuning modifications and all table references and images are taken from EFILive software.

BTM – Brake Torque Management

One of the biggest performance killers at least for my heavily modified 383 was BTM. There are lots of rumors out there about exactly what this does like preventing tranny shocks from neutral drops, prevents tranny from seeing more power than anticipated, and so on.

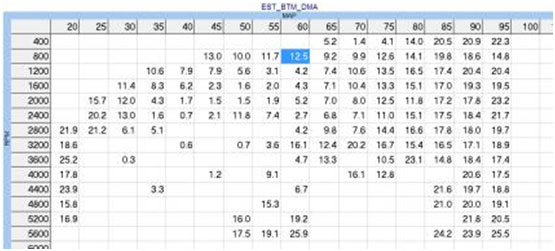

From my one experience I’ve seen it pull timing as much as 30 degrees for no other reason, as far as I cold see, than the engine was making more power than what the computer expected. See table below which shows a log of timing that is being pulled in reference to RPM and MAP readings.

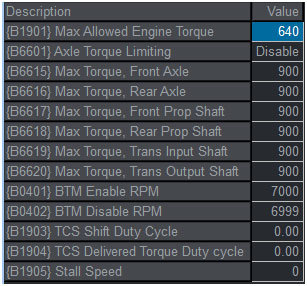

As far as removing or reducing BTM, use the following tables in the tune.

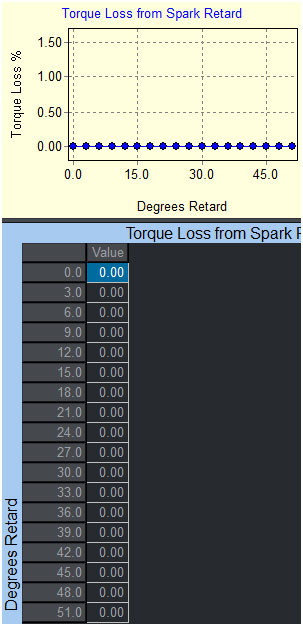

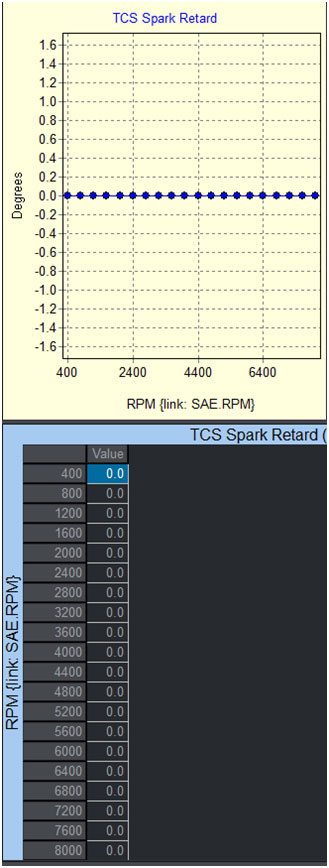

{B1902} Amount of torque lost from a traction control system (TCS) spark retard.

I originally maxed the table out thinking that it would disable it. In some operating systems that works, in other zeroing it out is what you want to do. Pay attention to the table description and values in your specific operating system to understand which direction should be taken.

Burst Knock

Once I understood what this was I personally thought it was pretty dumb. Basically the computer will pull timing when there are drastic changes in throttle position. Meaning basically that there is no knock but computer pulling timing because it's possible that knock will occur under these conditions.

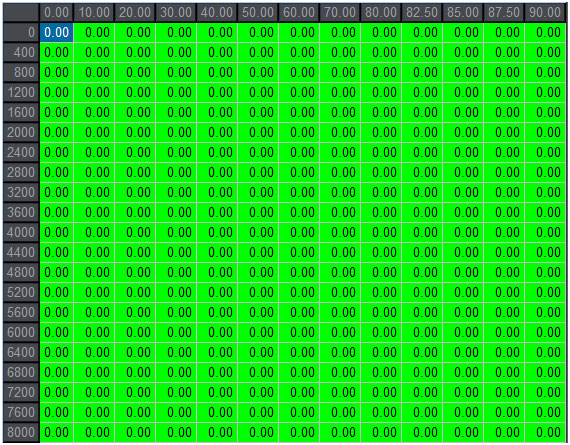

{B6212} - Burst knock will retard or advance timing upon detection of a large change in intake air mass.

If the change in air mass exceeds the values in {B6210} "Burst Knock Delta Air Mass", then the values in this table will be subtracted from the final spark value. Zero this table

{B6210}- When a change in cylinder air mass exceeds these calibrated values, burst knock can be enabled. Set all in table to: 0.564374

TCS – Traction Control System

Believe it or not even on our early OBDII trucks it is possible for the PCM to use TCS. It's important to remember that we may not see all of the algorithms that use these tables in order to disable them. So even though TCS or BTM is disabled there may be something in the OS still attempting to use those tables.

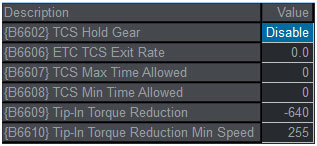

{B6603}-Spark retard to reduce engine power when traction control is active.

{B6604}- Initial spark retard as soon as traction control system (TCS) is active before changing to the TCS spark retard table {B6603} "TCS Spark Retard".

{B6605}- Spark retard required to cause the desired engine torque loss.

This is referenced back to "Mean Best Timing".

Zero these tables

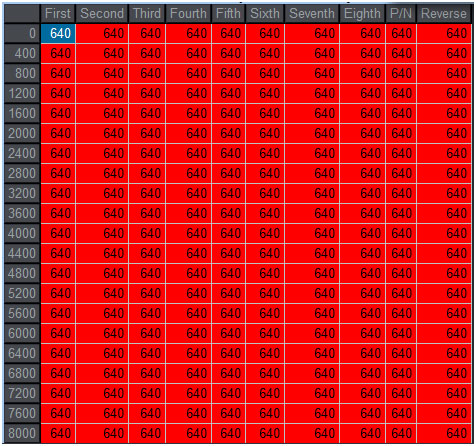

{B6611}- This table is used to determine the max torque allowed by gear. The traction control system (TCS) will use these values to reduce the engine torque.

Max This table out

{B6612}- Used to limit the percentage of electronic throttle control (ETC) opening for a given torque reduction percentage.

Zero this table (Probably already zeroed in cable throttle vehicles.)

{B6613}- Engine must be running for this long before the traction control system (TCS) can override the electronic throttle control (ETC) or spark.

{B6614}- This table defines the maximum allowed engine torque by RPM for vehicles with ETC.

Zero these tables if they aren't already.

Further enhancement

Of course these are just simple alterations to get you started. In order to truly see the most significant increases in performance, economy, and longevity, you will want to do full VE correction, fueling table changes, spark map alterations, and some transmission tuning. However those are subjects for another day.