By: HellKnightHicks

February 16, 2015

Please read the disclaimer page

Please visit our FORUM. All discussion, questions and comments about this article are welcome.

The specific vehicle setup tuned in this article consists of a 383cid engine, marine intake manifold, slightly aggressive cam, 4l60e, 411 PCM with Express van base OS.

While in discussing the steps in this article were performed with this setup, these procedures will work with most any cam or engine setup.

Issues this resolves or helps with:

- Startup

- Transitions from P/N to Drive

- Low speed Turning with low idle

- Stalling at low speeds

- Erratic Idle

Summary

After some fighting and fussing with my engine I discovered some information that drastically helped startup and transitions from P/N to Drive and low speed transitional fueling (i.e. around in parking lots).

I like a low and rumpy idle that shakes my truck at a light. To achieve that, I idle at around 600 RPM. This means that power steering and hydraulically assisted braking can kill the engine due to the cam. The changes we will discuss drastically helped me with the problems I was having due to my cam. They work well with Automatic or Manual transmissions.

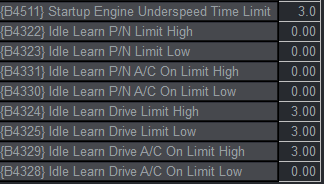

Idle Learn time settings:

Aggressive cams take longer to find idle than a stock cam would. We can change the following values to be a little longer, in order to allow the cam to settle down after an increase in RPM or just starting up.

After modifying these settings the STITs (Short Term Idle Trims) will settle more predictably.

This also helps prevent idle swing up and down because the computer will make adjustments at a slower rate allowing the cam to settle into an idle speed instead of being bounced around.

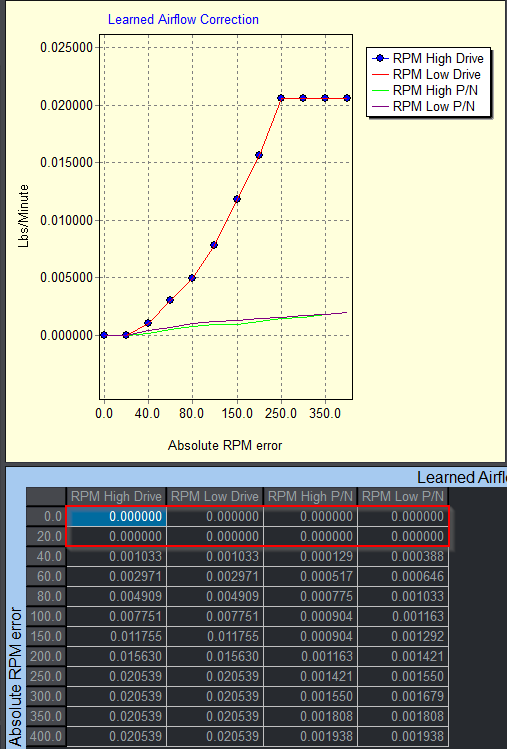

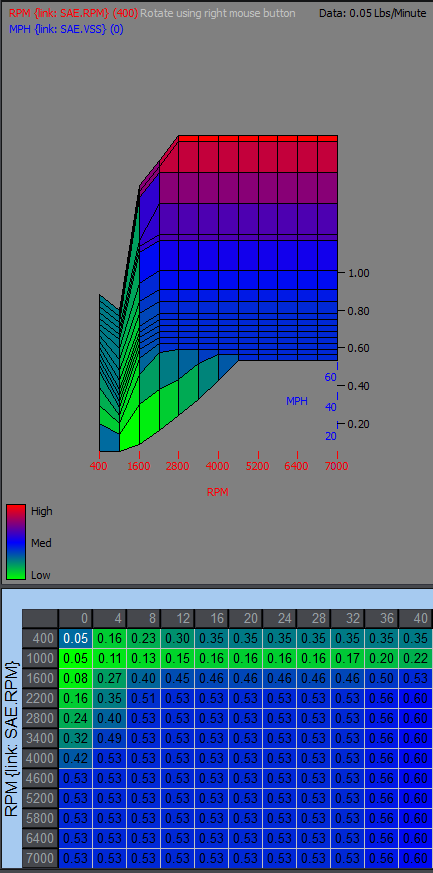

Learned Airflow Correction {B4514}

“Correction to learned airflow when engine speed is too high or too low and transmission is in drive or Park/Neutral.”

With a more aggressive cam, idle will float around a little even on a good day due to the chop and low torque accessiores turning on and off.

So we don’t want the PCM making adjustments if were close to where we should be idling.

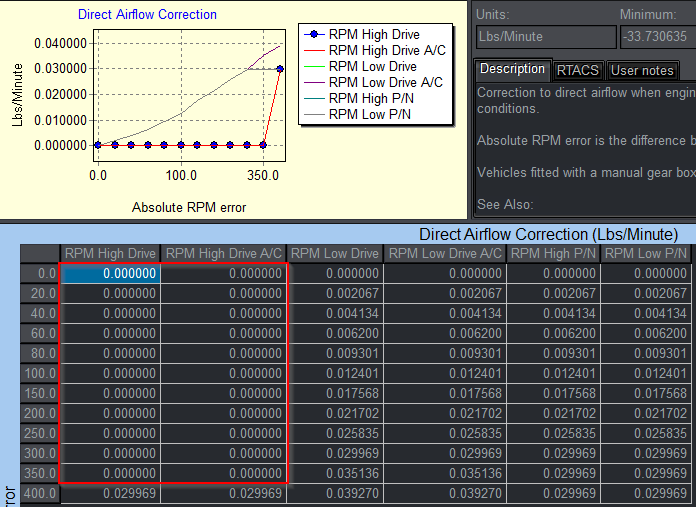

Direct Air Flow Correction {B4515}“Correction to direct airflow when engine speed is too high or too low under various transmission and A/C conditions.”

Since the cam is no longer stock, the adjustments made by this table are rather drastic. Aftermarket cams seem to like more air than a stock cam at idle and do not like drastic reductions in airflow.

Zero the red boxed values above to prevent idle adjustments when within 20 RPM of commanded Idle speed.

If we’re idling higher than desired by a few RPM’s we’re not very worried about it. If we’re low, a good push back up will help save us from a stall out. Adjusting the red boxed values above will help make the PCM more sensitive to the needs of an aggressive cam. This is not the only table that adjusts idle so allowing over speed here is fine in my experience. My engine finds idle much better now.

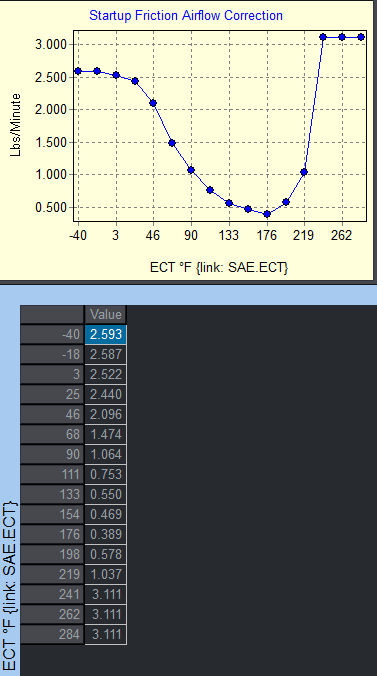

Startup Friction Airflow Correction {B4343}

Increasing the values in this table will help with starting. I have problems when starting in colder temperatures but don’t have any issues when starting on a warm day. The values I changed were down in the lower temperatures. This adjustment will disappear about 30 seconds after starting. If you find you need extra air when starting your engine, this is a great way to do it. You can go quite wild in this table safely. I’ve seen others with values as high as 14 at -40 Degrees F. My changes are not that aggressive but suited my needs.

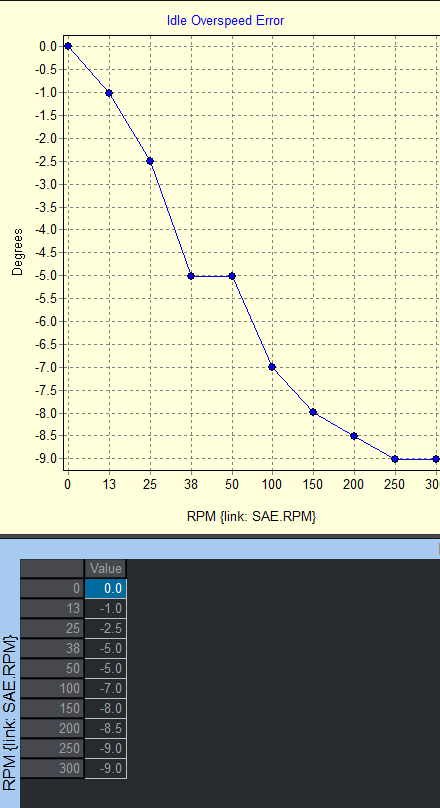

Idle Overspeed Error {B5935}

If the actual idle speed is above the desired idle speed value, then this table is used to make adjustments to spark timing. The RPM error values are in relation to the difference between actual idle speed and desired idle speed.

This table is too aggressive in the stock configuration for an aftermarket cam. If we’re over speed we need a slow adjustment to timing to bring it down.

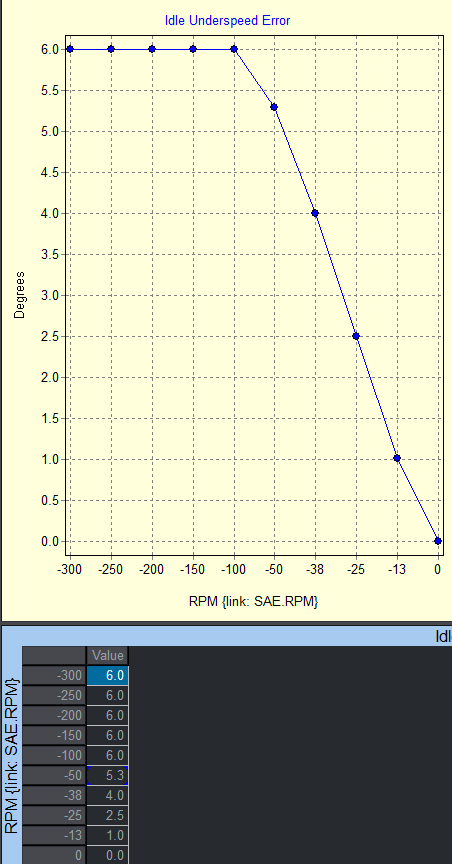

Idle Underspeed Error {B5936}

If the actual idle speed is below the desired idle speed value, then this table is used to make adjustments to spark timing. The RPM error values are in relation to the difference between actual idle speed and desired idle speed.

If we’re falling on our face we need a more aggressive adjustment here compared to stock.

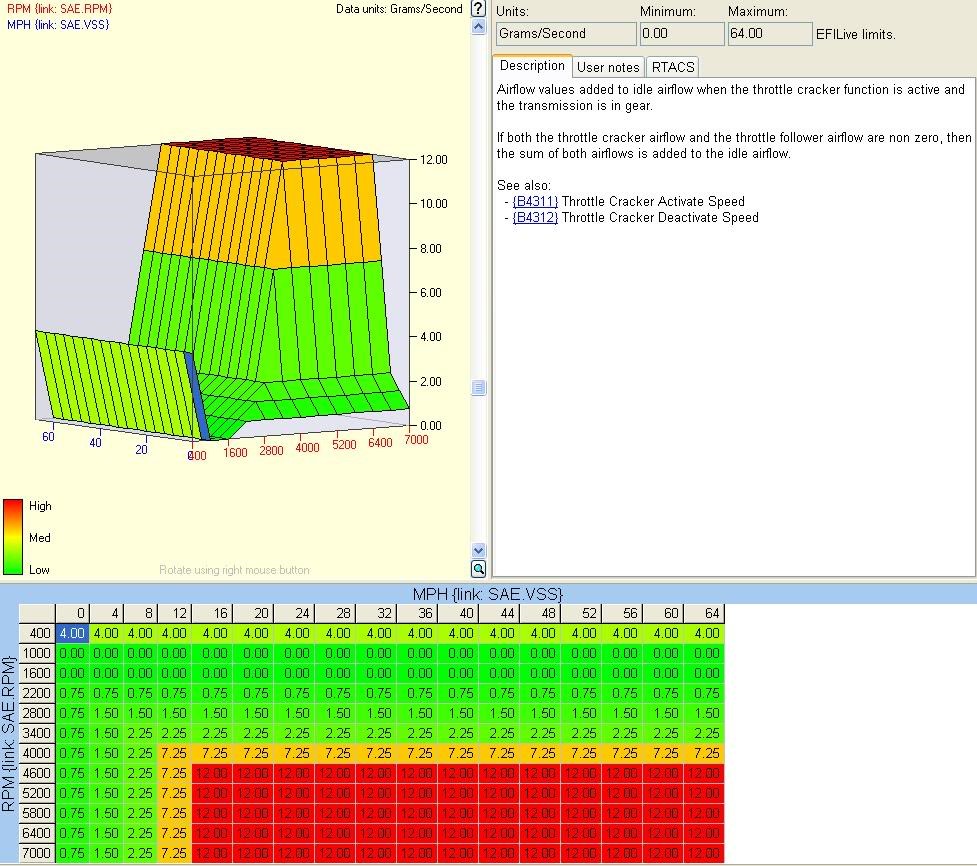

Throttle Cracker Airflow in Gear {B4309}

“Airflow values added to idle airflow when the throttle cracker function is active and the transmission is in gear.”

Just to add a little stall saver when in gear, you can take the 400 row and increase the values to add a burst of air if your engine starts to stall. You can do this mildly or aggressively as you see fit. Mine is mild because I idle so low. With a higher idle speed you can get more aggressive with this table.

You’ll have to play with this one for your desired effect. But these examples are 2 good starting points.

Mild:

Aggressive:

After all of this a good next step would be the RAFIG Process which can be found here:

https://forum.efilive.com/showthread.php?5866-Auto-VE-questions&highlight=RAFIG