by:Hquick

Please read the disclaimer page

Please visit our FORUM. All discussion, questions and comments about this article are welcome.

This article will discuss the installation of a Walbro 255lpm pump into a 1998 GMT400 stock carrier.

The Walbro 255

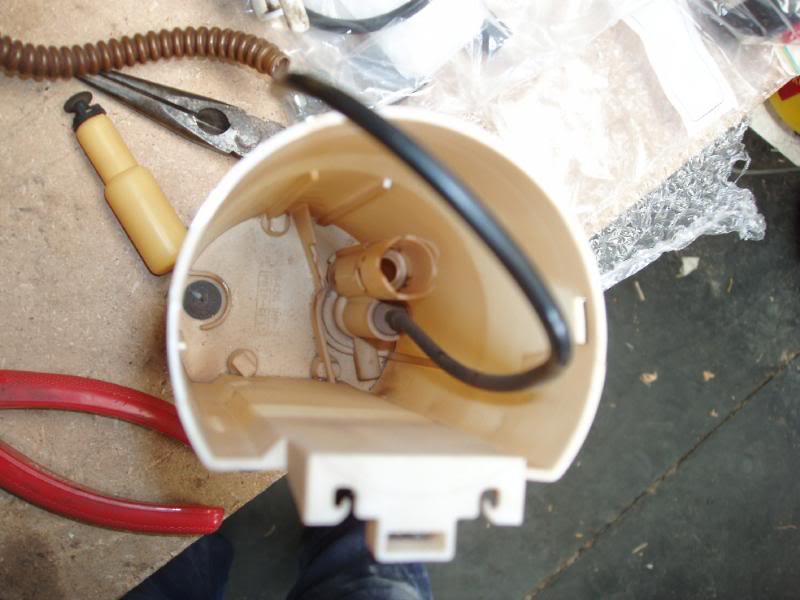

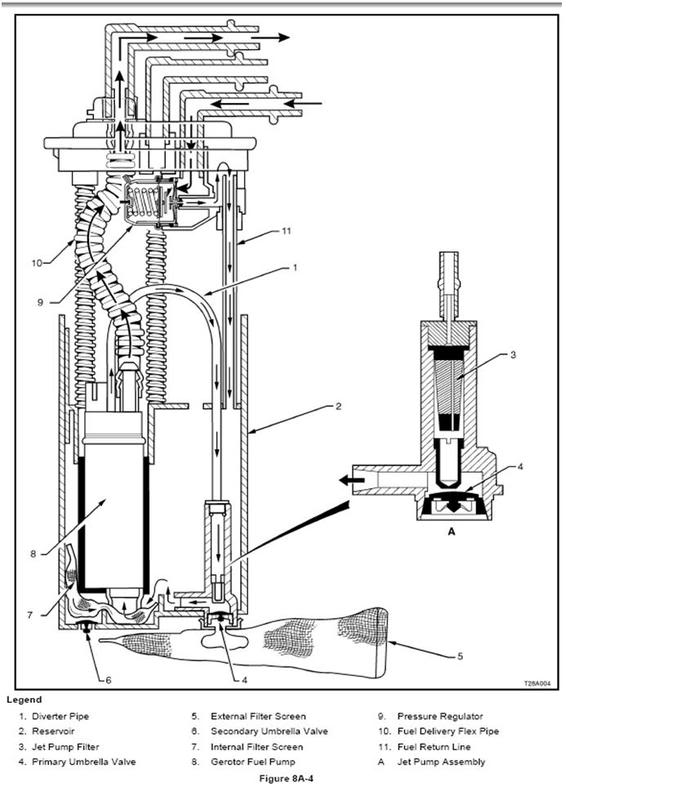

The old pump has a small black tube coming from a venturi pump in the bottom of the bucket to a nipple in the top of the pump.

This small pump (actually more like a valve) is designed to keep the fuel 'bucket' full so s not to overheat the fuel pump.

Stock Pump on the Left, Walbro on the Right

Some general pic's

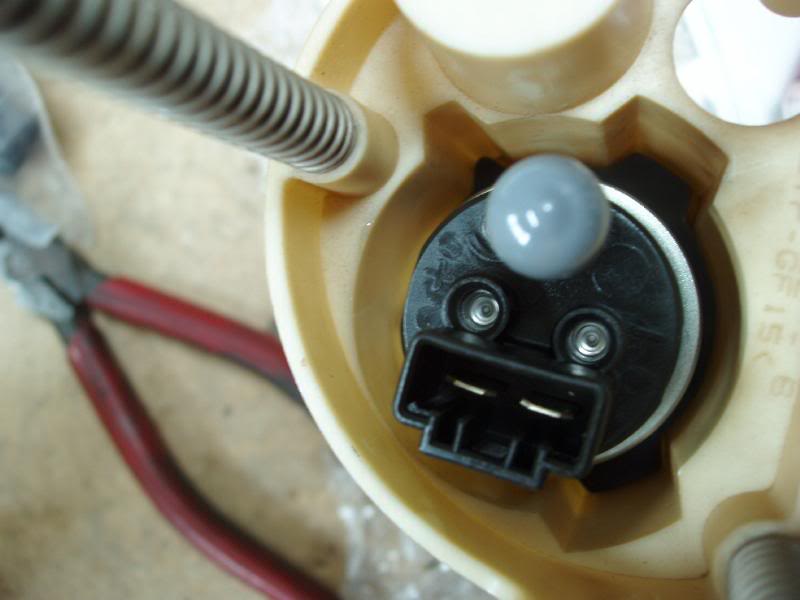

Sender unit..

With the aid of Vaseline....I managed to get the original rubber sleeve onto the Walbro (it's slightly larger in diameter to the OEM pump...but I got it in there. I've heard the Walbro's are LOUD if you don't use the rubber sleeving provided...figured this would be better still)

Makes for a neat fit!

Sender and carrier flow schematic

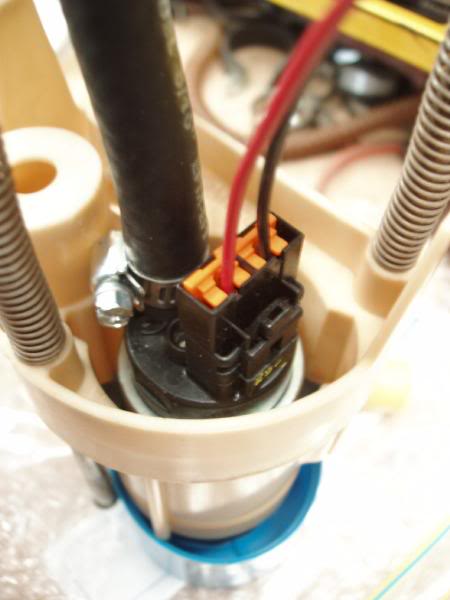

Cleaned all the elec connections and started assembling the unit.

Here's why we can't cut that small 'jet pump' barb out of the OEM pump and install it into the Walbro...

So I've decided to go with the 'T' idea. I'll make up a 'T' from a 3 way fitting tomorrow at work.

I used a little Vaseline around the outside of the rubber 'sock' which the pump sits in and pushed it into the carrier until it was fully seated

I then 'test fitted' it all into the bucket.

I installed the rubber fuel line which came with the Walbro kit.

I re-used this filter sock (mainly just because everything takes too long to get here...and I want to get this done.

I cleaned it out with some elec parts cleaner and it seems OK. It's a fairly coarse filter. The finer one is attached to the bottom of the pump 'inside' the bucket.

Attached the 'adaptor' plug which comes with the Walbro kit.

Re-attached the sender unit/float.

Now to drop the tank and do the swap.

Installed the 'in bucket' filter on the bottom of the Walbro pump and re-assembled the whole unit.

So...I picked up a 5/16" straight through hose barb.....

Filed a flat spot in the centre and drilled a 4mm hole in the flat section.

I then filed the stepped section off the nipple I removed from the old pump.

I then fitted the small nipple into the flat spot on the double ended hose barb (ready to be silver soldered).

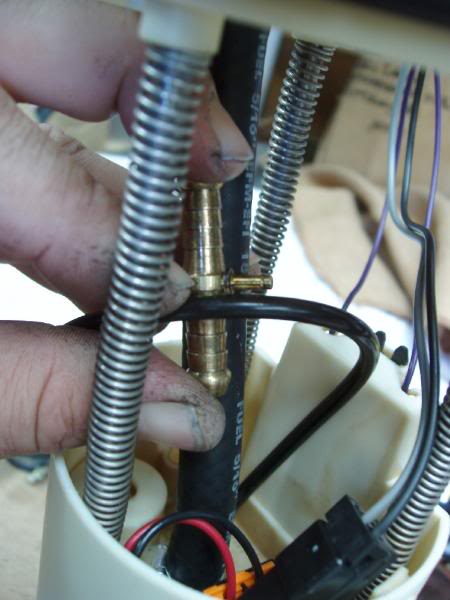

Here's where it fits into the main fuel 'outlet' line.

Silver soldered that 'T' piece.

Pulled the fuel pump relay with the truck running and let it idle until out of fuel....to take the pressure out of the lines.

Dropped the tank and removed the old pump.

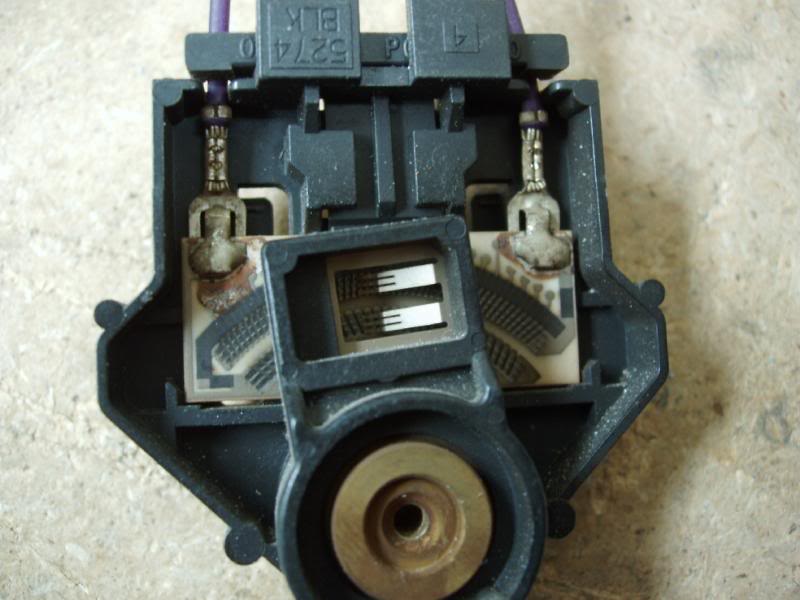

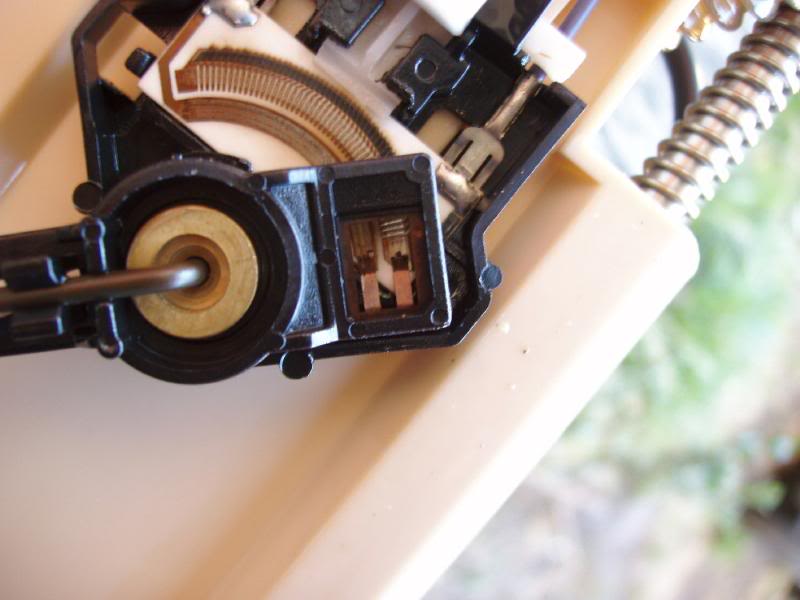

Found the cause of the jumpy fuel guage...see the little fingers/contacts are worn away.

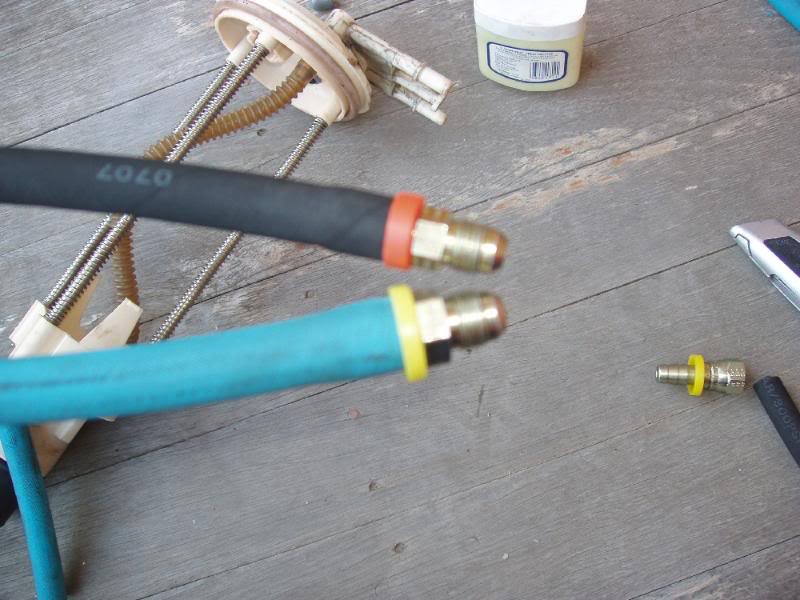

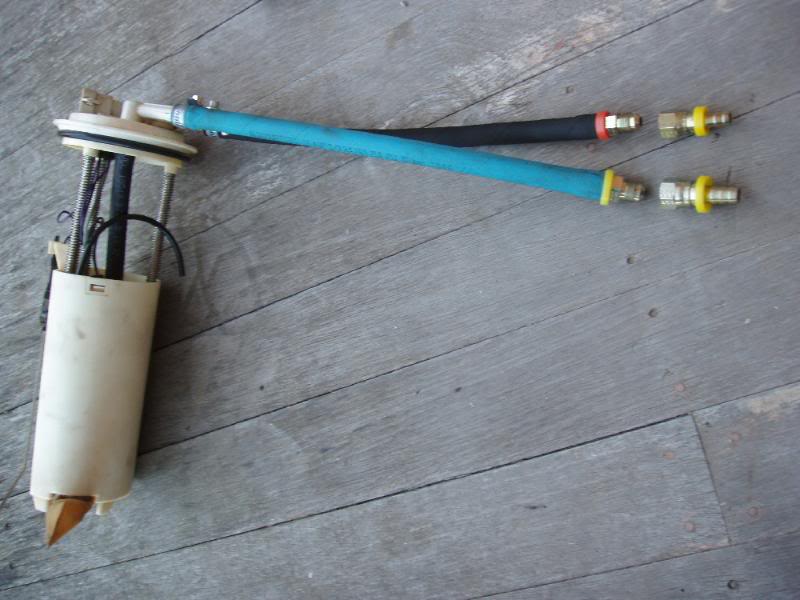

Ruined the little tabs inside the 'quick connect' fittings whilst trying to remove the fuel pump so decided to go with a new...better setup.

And the existing fuel lines....I cut the 'quick connect' (almost impossible to disconnect) fittings off and inserted the Aeroquip 'pushlock' fittings.

Next I measured the depth of the fuel tank and cut the main fuel 'outlet' line and inserted the 'T' piece.

Original Discussion located here, everything used with the author's approval

To comment, discuss, or ask questions about this article, please click here to visit our forum.