By: Aloicious

Feb. 12, 2012

Please read the disclaimer page

Please visit our FORUM. All discussion, questions and comments about this article are welcome.

Welcome to part one of the fuel injector series where we will discuss fuel injectors in depth, from their basic function, to advanced topics like injector dynamics and tuning.

Part one of this series on fuel injectors is on the basics on fuel injectors, their basic design and function. For those familiar with fuel injectors, much of this part may be review. But let’s begin…A fuel injector is basically an electrically controlled on/off valve which allows fuel to flow from the pressurized fuel system into the engine to be used.

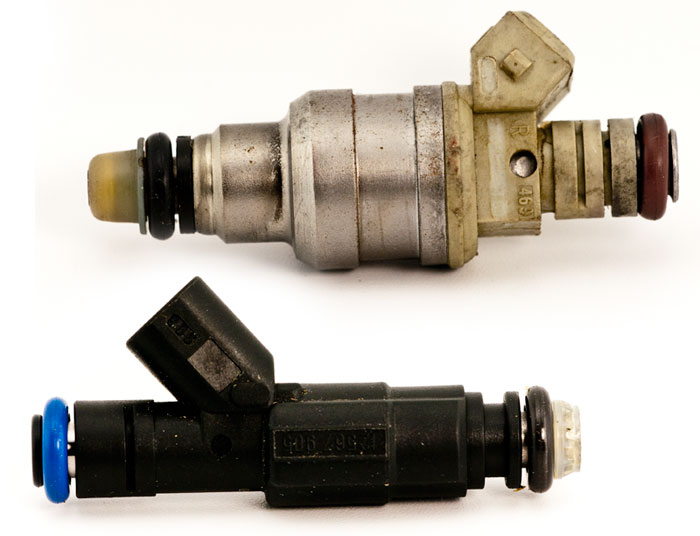

There are different types of fuel injection as well as fuel injectors. You may have heard of TBI (throttle body injection), MPFI (multi-port fuel injection), CSFI (central sequential fuel injection), TPI (tuned port injection), etc. All of these different types of fuel injection have the injectors placed somewhere in the intake tract be it at the throttle body, or along the intake runners just prior to the intake valves, or elsewhere. There is also another type called direct injection which injects the fuel directly into the combustion chamber. Now for the most part the basics of how the different injectors function are essentially the same, with some variations here and there, but the core principles are the same. We will mainly focus on the port injectors in this series as shown below.

Now, how does a fuel injector work? It’s a pretty simple setup, the injector has 2 wires going to it, one which supplies a switched 12V signal, and another wire which provides a controlled ground signal. Typically the PCM/ECM uses the ground to control the function of the fuel injector, and to control the amount of fuel that is injected. When the ECM wishes to turn ‘ON’ the fuel flow, it will supply the ground and complete the circuit to the fuel injector for a specific time period. When the circuit is complete, the electrons flow through the fuel injector body and energize an electromagnetic coil on the inside of the injector body. This electromagnetic coil creates a magnetic field which lifts some sort of seal (typically a pintle, disc, or ball) off its sealing seat, and this allows the pressurized fuel to flow and be injected. When the injector controller removes this ground, the electromagnetic coil discharges, and the magnetic field dissipates, a small spring then pushes the seal back against its seat and stops the flow of fuel. This whole process happens many times per minute for each injector.

Here is an illustration demonstrating this process. (Image taken from Wikipedia, used under license)

It is an elegantly simple but useful design. So now that we understand what injectors are, and basically how they work, in the next part of the series, we will be discussing how the fuel supply is controlled in a bit more detail with pulse widths, and duty cycles.

Next: Part Two: Injector Duty Cycles and Pulse Widths

To comment, discuss, or ask questions about this article, please click here to visit our forum.