By: Aloicious

Apr. 5, 2012

Please read the disclaimer page

Please visit our FORUM. All discussion, questions and comments about this article are welcome.

Now that we understand what fuel injectors are and how they function, we need to look at how to choose the correct injector for your setup.

First we need to understand the different styles and types of injectors that you need to look at. First off there are 2 different types of injectors, Peak and hold (aka low impedance) and saturated (aka high impedance). The injector drivers within the injector controller are created to operate a specific injector type. YOU MUST USE THE CORRECT INJECTORS FOR THE INJECTOR DRIVERS YOU HAVE. Damage can occur from using the improper injectors, for example, if you use low impedance injectors with high impedance injector drivers, the injector drivers can get overloaded and fried. And if you are using a PCM to drive the injectors, that means your PCM gets fried. Have fun with that. If you are unsure what injector drivers you have, most of the time, you have high impedance injector drivers, they are by far the most common type. You can also measure the impedance of the current injectors you are running with an ohmmeter. Low impedance drivers and injectors are typically used in aftermarket setups, or typically very high flowing injectors.

Saturated injectors are the most common type, they operate at around 12-16 ohms. These are the types of injectors that we have been talking about the majority of this fuel injector series. Most factory injectors are saturated high impedance injectors. High impedance injectors are common, inexpensive, and reliable. However, they run slightly slower than low impedance injectors, and typically had difficulty handling very high flow rates.

Peak and hold injectors, or low impedance injectors typically operate around 1-6 ohms. These injectors are most commonly found in aftermarket systems or systems that require very high flow rates. Low impedance injectors are faster than high impedance injectors, and can handle very large flow rates much better. However they are less common, they can be more expensive, and can run hotter which can lead to premature failure.

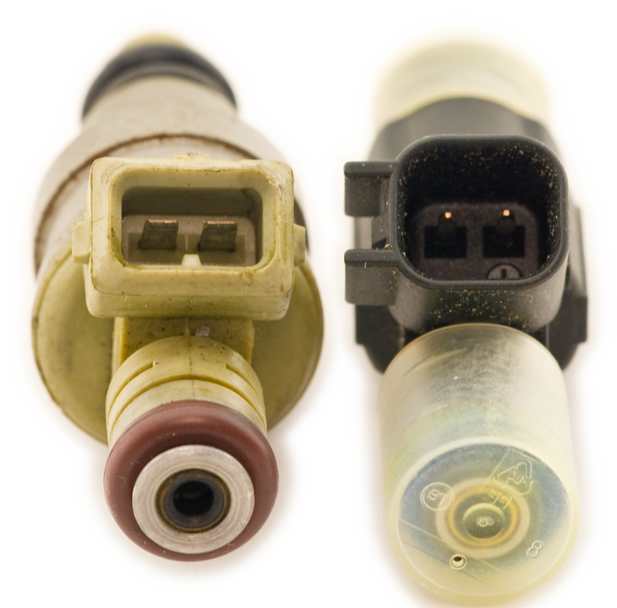

So, you'll also need to know what kind of injector connector setup you need as well. There are various different injector connector styles including EV1, EV6, Delphi, Honda, Toyota, Nippon-Denso, EV14, and others. For our purposes, we will mostly be dealing with the EV1 and EV6 styles. Below, the black injector on the right is an EV6 while the one on the left is an EV1 style.

You should get the style that matches your connectors. If you want a different injector than the connectors you already have, you can re-wire them, or you can get a conversion connector to change the connector style that you want.

Okay, so now to the million dollar question...What flow rate injectors should you get? Well, that depends on a few things. In order to calculate the flow rate you'll need to know your horsepower goals, your engine's brake specific fuel consumption (BSFC), the maximum duty cycle that the injectors should see, and the number of injectors you'll be using. The formula for calculating this is:

There are different BSFC values for different engines, basically the BSFC is related to the engine efficiency, but for these calculations, 0.48 - 0.55 for stock and mildly modified performance engines, 0.45 - 0.50 for performance engines with quality heads, 0.55 - 0.60 for supercharged engines, and 0.55 - 0.65 for turbocharged engines. For the duty cycle, you'll want to use 80% since the max duty cycle that you want to see from the injector for the reasons we discussed in the injector dynamics section. After you do the calculations, you'll want to round up to the closest injector size that is made.

For example, a 400hp performance engine with a BSFC of .50, 80% max DC, using 8 injectors needs 31.25 lb/hr injectors...however since 31.25 lb/hr injectors aren't made, you'd be looking at 32 lb/hr injectors.

You can use the fuel injector calculator on our calculator page to do these calculations for you. You can also do other injector calculations from there as well.

However, don't forget that an injector's flow rate is directly related to the fuel pressure of the system. The advertised flow rate for most injectors is at 3 bar pressure (43.5 psi), some are tested at other pressures too, so look for that information while shopping around. If your fuel system runs at a different pressure (like 4 bar (58psi) that many GM systems run at), you'll need to take that into account to get the actual fuel flow rate of the injectors on your system. There is also a calculator for that on our fuel system calculator page as well.

Well, that is about it on choosing your injectors. Now that you've found your dream injectors, you'll need to tune the controller for them. We'll tackle that in the next, and final, section of our fuel injector series.

Next: Part Five - Injector Tuning (coming soon)

Previous: Part Three - Injector Dynamics

To comment, discuss, or ask questions about this article, please click here to visit our forum.