by: HellKnightHicks

Thanks to: Shwa Kid, Raven2510, s10cyncrvr, and blanz

Please read the disclaimer page

Please visit our FORUM. All discussion, questions and comments about this article are welcome.

Given that none of the adjustments to be made list the exact torque to be used you should use your best judgment and make sure not to overdo the gear box adjustment. GM truck central and Hellknighthicks do not accept responsibility for misuse or damages caused by performing these modifications.

So you want to know some things you can do to tighten up the steering in your aged OBS GM truck. There are a couple of free things you can do to tighten up the gear box for the steering.

1 Set bearing pre-load

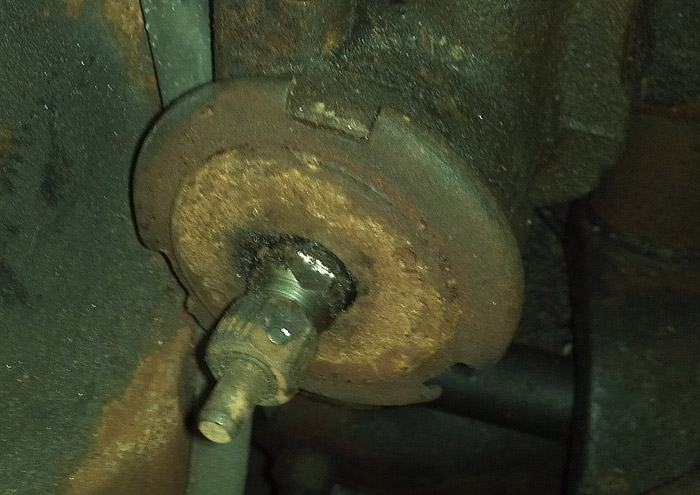

This is done by removing the retaining ring and the preload nut/washer …. Whatever you call this thing

You will most likely have to take you steering shaft out to do this properly.

Once the shaft is out you can perform the first of 2 adjustments

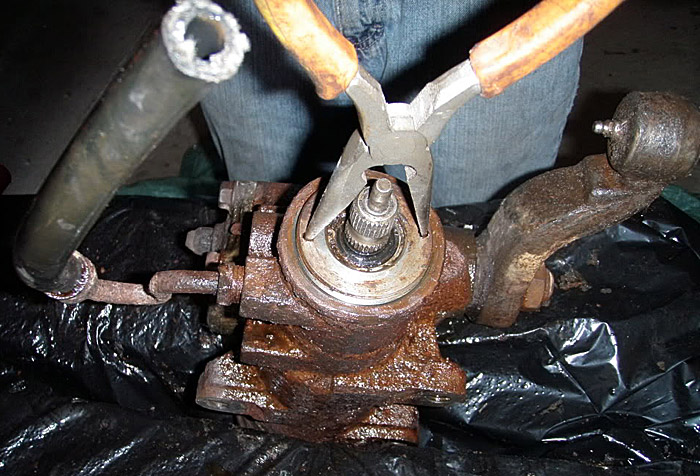

Remove the locking ring…. Then tighten the center disk snug…. Not grizzly tight just to where to where it doesn’t move easily… I used a pair of punches.

Once you have tightened back it off 3/16" to 1/4" at the perimeter of the disk. (You can mark the box and the disk then measure the space)

2 Set Over Center adjustment

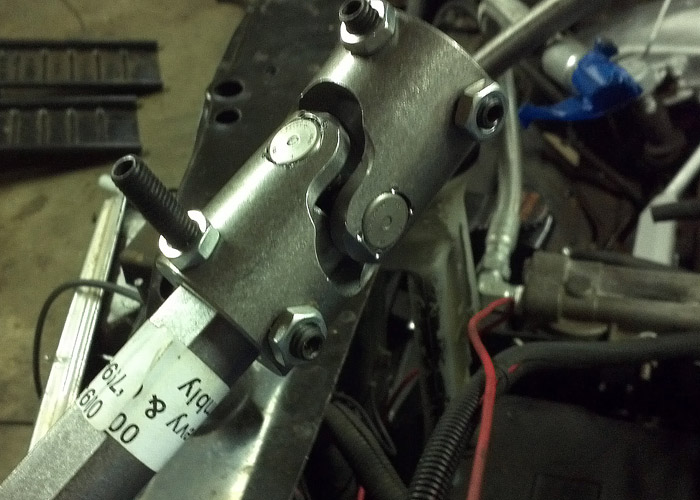

Now the second thing you can do to tighten the gear box is the Over Center adjustment.

First you’ll need to locate the center position of your gear box. A good way to find this is to start by counting the turns from lock to lock. What I did was jack the front of my truck up using the proper jack stands on either side then turned from lock to lock counting the rotations of the steering wheel and then going back half that amount. Once you’ve located the center position of your steering box your ready to set the preload.

So as depicted above you’ll need a wrench to fit the lock nut and a proper sized Allen wrench for the screw. Tighten the Allen screw snug then tighten the retaining nut while holding the Allen screw. If possible rotate the steering shaft with an Inch-Lbs torque wrench and measure the amount of resistance required to pass through the center sweep. You should see no more than 14 Inch-Lbs at a constant rate. Note- It’s expected that the steering will be stiffer at center than closer to the locks.

3 Remove the rag joint in the steering shaft

Removing the rag joint

There are 2 different approaches you can take here.

Option #1

Borgeson makes a steering shaft that has U-joints in it.

762 BORGESON STEERING SHAFT 935 79-94 Chevy/GMC Full Size Trucks & SUV's

Its rumored that for some legal liability related to the Air Bag system Borgerson does not claim to support the 95-99 trucks with this shaft. However it does work and no one at this point that I’m aware of has reported an accidental discharge of their air bag system.

Pros

- 2 U-joints great for lifted trucks with odd angles of steering geometry

- Long Telescope shaft Extends some 30”

- Thick steel Construction

- Rigid

- Solves the problem

Cons

- Price rather expensive $200 - $270 (Mine was $223 from klmstore.com)

- There is not protective coating on the shaft and it will rust without something

- You must cut 5” off the end of the shaft to fit a stock height C or K 1500

- Once the shaft is cut you must drill a retaining hole for the upper U- joint.

Now that that’s out of the way, let’s get started.

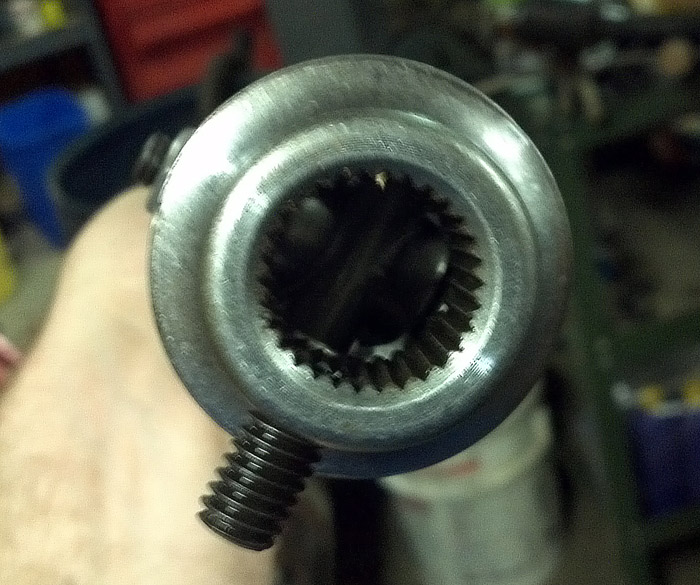

Here are some glamour shots of the shaft.

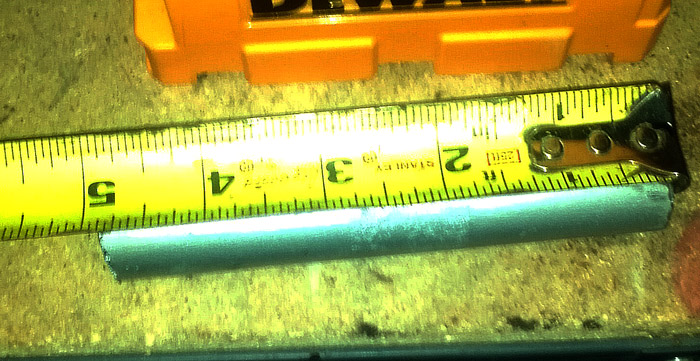

Here is where I lined my new shaft up to see how much needed to be removed.

Note: You should always check measurements using your own setup. Just because 5” was perfect for my truck doesn’t mean it will be the same for yours. Project truck shown is a 97 k1500

Remember that you have to account for the Upper U-Joint your adding in.

Mine came out to be about 5” that needed to be removed from the shaft while it was fully collapsed.

You’ll need to drill a hole in the side of the shaft that matches up with the retaining screw. This screw goes in one side and puts pressure on the other side of the shaft… So don’t drill the whole all the way through. Just threw one side. If you need a reference as to what I’m talking about you should look at the bottom U-join on the Borgerson shaft do the same thing they have done… Probably need to add an image for that here. But I’m not taking mine back apart lol.

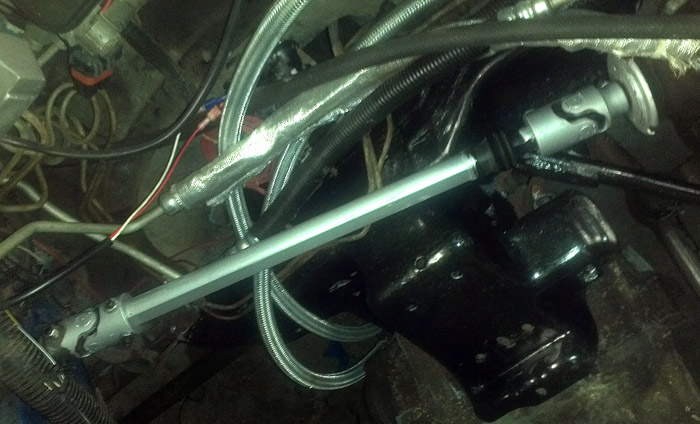

And here she is all put together...

I coated my shaft with rust bullet to prevent rust.

Make sure to go through all of the Allen wrench screws and tighten them up good… Then tighten the Retaining nuts.

Option #2

Flaming River U-Joint # FR1746DD

Pros

- Billet aluminum

- Wont rust

- Solves the problem

Cons

- Price $70 - $100

- More work than Borgerson shaft in my opinion

This option requires a little more work in my opinion than the entire shaft replacement.

First you’ll want to take you stock steering shaft out. Then remove the rag joint.

To remove the rag joint you must us a dermal or small cutting wheel to put a slit in the rag joint housing

once you have provided a means for the housing to open some you should be able to hit the housing with a hammer and drive it off.

Now you’ll need to cut the flared end off of the shaft.

There should be about ¾ of the shank left after doing this.

It’s advised that you take a drill bit or dremel and dimple the points on the shank that the new u-joints set screws will hit. This will assist with retention.

Now install your new U-Joint … You may want to use lock tight to ensure the set screws stay in place

Now simply reinstall the shaft.

Ether option you chose I think you’ll be satisfied with the improvement in the steering system performance. One possible negative is that the removal of the rag joint will allow a little more road vibration to be felt in the steering wheel as the original intent was to reduce vibration coming from the steering system. But this is negligible.

My personal opinion is that the Borgerson Shaft though the price is higher is the better of the 2 options. It designed better and is a more secure system as there is a retainer on each end that goes through the shaft at every U joint... So there's no worry that it will ever slip or move off the ends. The Borgerson Shaft is what I run on mine.

To comment, discuss, or ask questions about this article, please click here to visit our forum